Founded in 2009, SIL Group is committed to the highest standards of ethics, quality, and environmental responsibility. The company specializes in designing and manufacturing high-quality CNG and industrial gas cylinders for automotive and storage use across the globe. SIL has positioned itself as a pioneer in clean energy by focusing on innovation and sustainable development. With operations spanning five continents and a sales record of over 450,000 cylinders, SIL stands out for its technological excellence and customer-centric approach. The company boasts an annual production capacity of over 300,000 cylinders and offers a wide product range tailored to diverse needs. SIL’s philosophy centers on conservation, energy efficiency, safety, and continuous improvement. Its dedicated R&D Center drives innovation in safety and quality standards. Certified by international bodies like ISO, EN, IS, BS, and D.O.T., SIL is recognized as a global leader in the CNG cylinder industry.

Commitment to Quality & Global Compliance

Total Quality Assurance

Sarju Impex Limited adopts a rigorous Quality Control approach in the

development of various

types of cylinders in different sizes. Their Quality Assurance program begins at the earliest

stage — from the selection of raw materials — and continues through inspection, testing, and

every manufacturing step until the product reaches the customer.

Continuous Quality Control

Our mission is to deliver products that are not only functionally reliable but also adhere to

the highest safety levels, aligning with international quality requirements.

SIL guarantees consistent high-quality products through:

Certification & Compliance

To maintain their global credibility, SIL ensures compliance with various

international and

national standards. Their production units are ISO 9001:2000 certified, reflecting their

adherence to quality management systems.

Standards Followed:

Production Process Flow

Our manufacturing process for SIL cylinders ensures unmatched quality and safety through a precise, multi-stage workflow. From seamless tube selection to final inspection, each stage is optimized for performance and compliance with global standards.

Key Initial Stages

- Seamless Tube Selection

- Tube Cutting & Wall Thickness Inspection

- Bottom & Neck Forming

- Heat Treatment & Milling

Final Stages & Testing

- Hydro, Cycle & Leakage Testing

- Ultrasonic & Hardness Testing

- Stamping, Weighing & Painting

- Final Inspection & Dispatch

Certificates

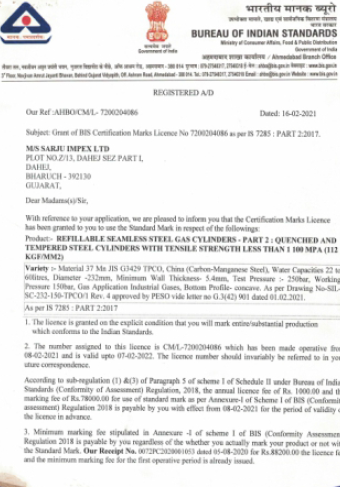

Front Side

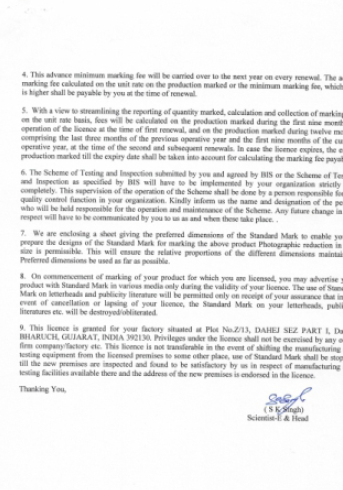

Back Side